The Project website will be continuously updated on regular basis and results will be published accordingly.

First Achievements ATM24

WP6

SiNERGY D6.4

First Achievements ATM18

WP2

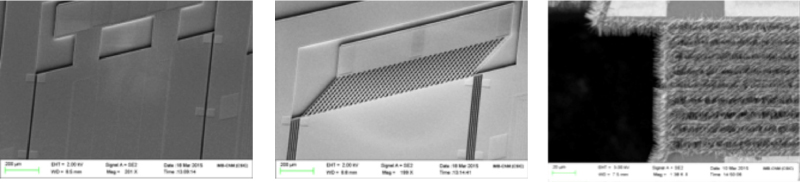

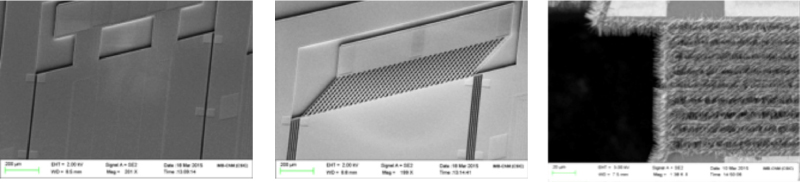

A technological route has been defined for improving the thermal isolation of planar thermo-generators based on silicon suspended platforms connected with Si nanowires. Conventional bulk silicon bridges have been substituted by sieve-like thin dielectric membranes. Dense arrays of bottom-up SiNWs have been grown laterally in such platforms by means of VLS-CVD after a galvanic displacement process for Au-nanoparticles seeding. Several trenches separating the hot and cold parts of the device were defined for even better thermal isolation and successfully filled with NWs, so that arbitrarily long nanomeshes could be obtained with just one short CVD process.

Figure : Suspended silicon platform linked by bulk bridges (left) or by a thin perforated membrane (center). Multiple trenches filled with bottom-up SiNWs (right)

WP2

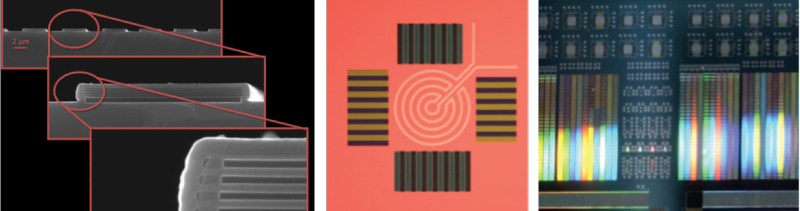

Top-down approach to the making of nanowire arrays. Alternate stacks of silica and silicon nitride are grown and lithographically defined onto a suitable substrate. Then transversal niches are obtained by chemically etching silica. Nanowires are then made by filling niches with silicon using chemical vapor deposition. The technology is scalable as it fully complies with microelectronic standards.

WP3

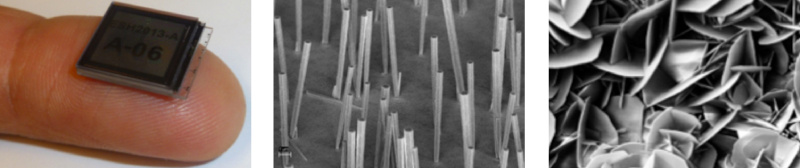

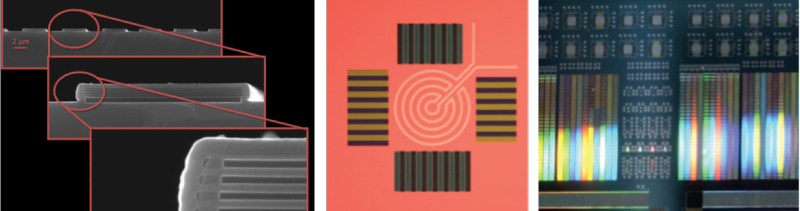

Two types of mechanical energy harvesters are being developed in parallel, able to convert vibrations into usable electric energy via a silicon spring-suspended proof mass and a variable capacitor. The piezoelectric harvester makes use of high performance piezoelectric ZnO nanostructures, synthesized by a newly developed, low cost, silicon friendly growth method. The electrostatic energy harvester uses a permanently charged high voltage inorganic electret material. Clever integration of cappings and stoppers limits the maximum displacement of the mass and improves the mechanical reliability of the devices.

Figure: Electrostatic harvester with glass cappings (left); Piezoelectric ZnO nanowires (centre) and nanosheets (right)

WP4

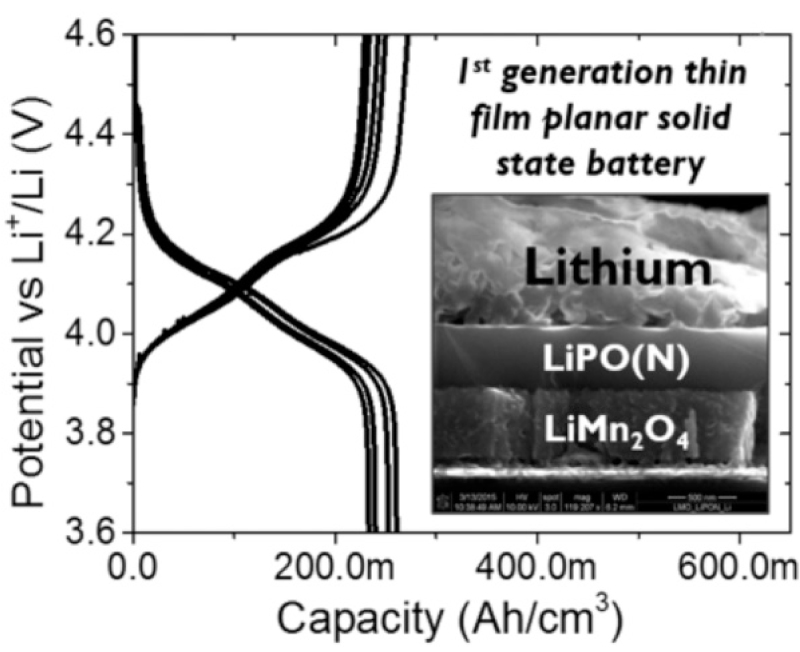

The SiNERGY 1st generation thin film solid state micro-battery has been fabricated and characterized. The battery stack consists of a LiMn2O4 cathode layer prepared by RF-sputtering and post treatment annealed, an electrolyte layer of LiPON prepared by RF-sputtering using N2 flow which has been known to have the maximum ionic conductivity and an anode layer consisting of a lithium metal thin film prepared by thermal evaporation. Cyclic voltammetry and charge-discharge measurements show that the device can obtain 250mAh/cm3 with high Coulombic efficiency of the stack showing high performance on kinetics.

Figure: 1st generation battery stack showing 250 mAh/cm3 of capacity

WP5

Leading the research towards energy efficient wireless autonomous sensors (EEWAS), thus aiming to meet the challenges referred to the specific technical requirements, the 2 proof of concepts devices will be engineered and based on the innovative micro.sp technology patented by STE. Micro. sp technology adopts an advanced concept of data transmission taking the advantages of an innovative modulation scheme capable to generate 2μs wide high peak power RF pulses.For the proven robustness, flexibility, economical scale and system’s scalability, along with the intrinsic ultra low energy absorption, the micro.sp opens up an innovative and previously unthinkable approach to EEWAS that is particularly proved to be suitable for the Tire Pressure Monitoring System and “white goods” commodities, that are representative products of the growing world of Internet of Things.

WP5

Gas-powered appliances are excellent candidates for a «thermal harvester » proof-of-concept. The reason is tied to the fact that such appliances usually do not have electricity on-board and are controlled by devices operated by fluid expansion (e.g. thermostatic gas control valve). Such types of appliances are quite diffused, particularly in the countries of the Mediterranean area where combustible gas (methane or LPG) has always been extensively used. As an example, a professional kitchen has a power consumption ranging between a few tens to a few hundred kilowatts. A thermal energy harvester capable to provide enough power to supply a sensor and a RF transmitter would give the great advantage of digitally managing a totally mechanical appliance.

The system will be able to read the oil temperature and to send its reading through the RF module to a remote controller along the entire working cycle of the fryer. Data transmission frequency will be typically of 0.1 Hz.